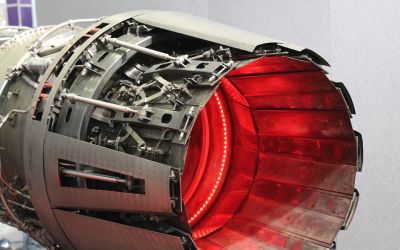

Remote visual inspection (RVI) tools are designed to help the aircraft maintenance crew perform a thorough inspection of aircraft engines without disassembling them. The two most common RVI devices that are used for engine inspection include fiberscopes and...

news

5 Factors that Affect Videoscope Inspection Results

Videoscopes are a vital piece of equipment used for the inspection of aviation engines. The visual inspection tool is used to detect the state of internal engine components without disassembly. Aircraft maintenance crew uses the device to inspect hard-to-reach areas...

Applications of Borescopes in Aviation Turbine Inspection

A borescope is a visual inspection tool that has varied applications. The tool is commonly used in aircraft and helicopter maintenance. Comprising a rigid or flexible tube with a lens on one side and the display monitor on the other, borescopes are used to inspect...

Borescope Care & Maintenance: What You Need to Know

A borescope is generally used to inspect different parts of an aircraft engine. Regular maintenance of the visual inspection tool is important to detect signs of wear and tear. Lack of proper care can damage your borescope and you may have to replace it. Here are some...

Tips for Selecting a Reliable Videoscope for Aircraft Turbine Engine Inspection

Videoscopes are used to perform visual inspections of the internal components of turbine engines. The device provides vital information on hard-to-reach areas of the engine. One can gain access to it by inserting the scope through the air inlet, igniter port, and specially designed access hatch for the borescope.

Different Types of Remote Visual Inspection (RVI) Tools for Aviation Engine Inspection

Technological advancement in the fields of remote visual inspection (RVI) has resulted in greater accuracy in aviation engine inspection. Modern RVI boasts improved imaging quality and advanced features that allow the maintenance crew to perform comprehensive non-destructive testing (NDT) of aircraft engines.

Best Practices When Using a Borescope for Helicopter Engine Maintenance

The use of borescopes is common in aircraft engine maintenance. Helicopter engine inspection requirements may vary, depending on the type of helicopter and the intended use. Most commercial and military helicopter engines have stringent inspection requirements since lives are at stake.

Aviation Inspection 101: Using Modern Videoscopes to Measure Tip Gap Clearance

Regular aviation inspection is essential to safe travel. Using a videoscope with precise measurement features can help prevent critical engine problems. One of the most inspection tasks made easier because of videoscopes is the tip gap clearance measurement. The...

How Borescope Inspection Can Prevent Common Aviation Turbine Engine Failure?

Borescopes have a long list of uses in aircraft maintenance. The technology allows aircraft maintenance technicians to inspect hard-to-reach areas of the engine. Modern borescope features high quality cameras that allow technicians to get crystal clear images of internal engine components.

4 Tips When Buying Borescopes for Helicopter Engine Inspection

Borescopes are optical devices that help identify any potential issues with a helicopter engine. Since several components of a helicopter are small and inaccessible, they can be reached using a high-quality borescope. Therefore, a borescope is a worthwhile investment that can save the time of your maintenance crew.