USA Borescopes Introduces the Next-Gen Small-Diameter Videoscopes Series for Industrial Inspections.

Small-diameter borescopes have revolutionized how industries conduct inspections and maintenance tasks in hard-to-reach places. Whether you’re working in aviation, automotive, manufacturing, or any other field that requires a precise visual inspection, selecting the right small-diameter borescope is crucial for ensuring efficiency and accuracy. This mini borescope content will explore key factors when choosing the perfect small-diameter borescope to meet your inspection needs.

Purpose And Application

The first step in choosing the right small-diameter borescope is defining the purpose and application. Different industries and tasks require specific features and capabilities. Are you using the mini borescope for routine maintenance, quality control, or diagnosing a specific issue? Knowing your primary purpose will help you narrow down your options.

These ultra-thin borescopes allow for viewing tight inspection areas that were normally inaccessible in the past. Although these small diameter borescopes are non-articulating, these inspection systems prove invaluable to inspection professionals.

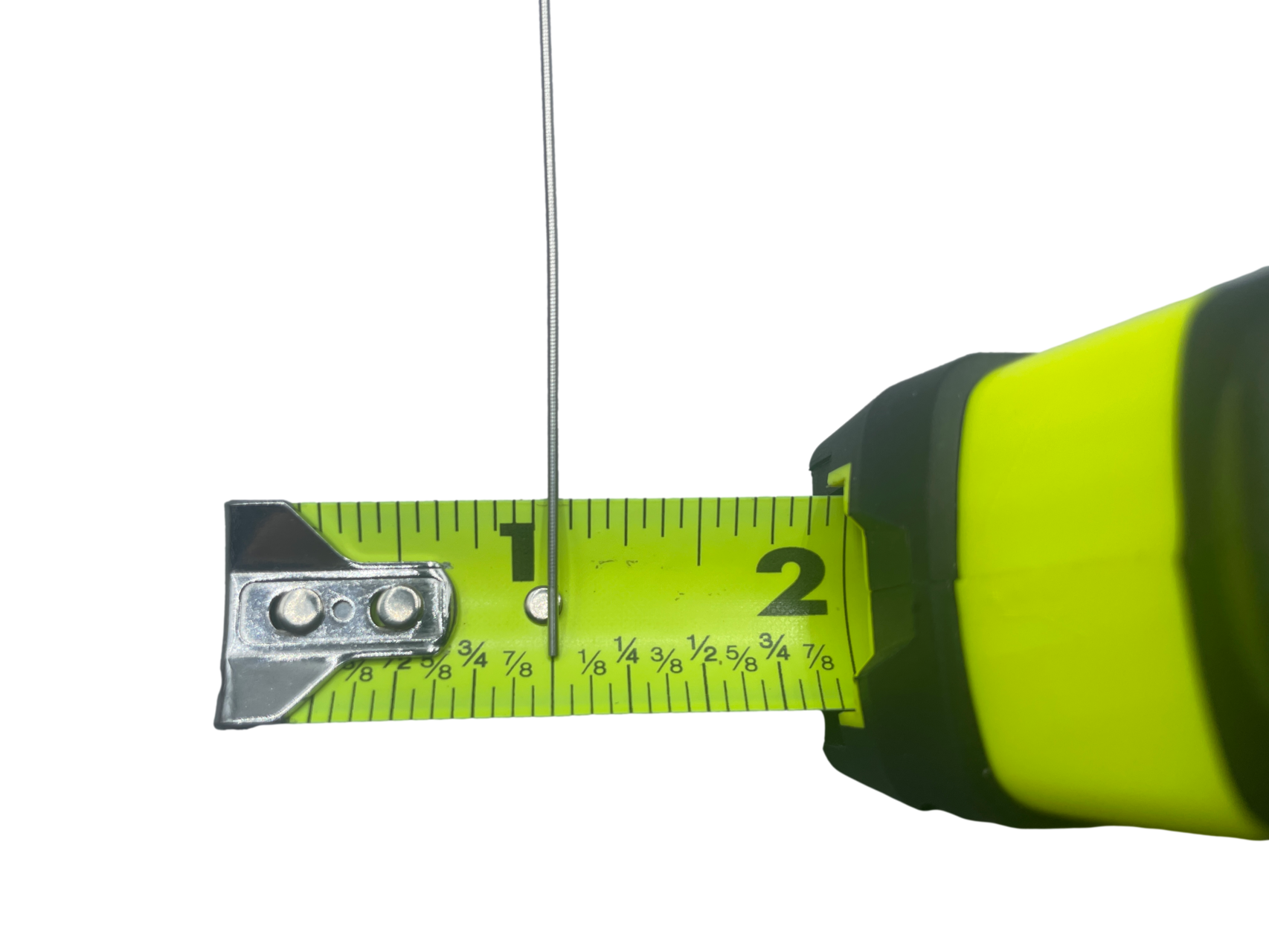

Diameter And Length

The size of the mini videoscope matters. Small-diameter borescopes are available in various diameters, typically ranging from 1.0mm to 2.0mm. The diameter you choose should align with the size of the openings or passages you must inspect. Smaller diameters provide access to tighter spaces but may sacrifice image quality, illumination, or flexibility. Conversely, larger diameters offer better image quality but may not fit in very small openings.

Consider the length of the borescope as well. Longer borescopes are necessary for inspecting deep or extended areas, while shorter ones are more manageable for close-quarters work.

Image Quality And Resolution

Image quality is paramount when selecting a small-diameter borescope. High-resolution imaging allows you to spot even the tiniest defects or anomalies. Look for a borescope with a high-definition (HD) camera or sensor and a good lighting system. Adequate illumination ensures clear visuals in poorly lit environments.

Articulation And Maneuverability

In many cases, you’ll need a small-diameter borescope that can navigate through complex pathways. Articulation capability is essential for achieving precise control over the camera’s direction. Some borescopes come with joystick-like controls to manipulate the tip, while others offer more advanced controls for 360-degree rotation and deflection. Choose a borescope with a level of articulation that matches your inspection requirements. As of 2023 the smallest articulating micro videoscope is 2.0mm, but with advances in technology and engineering efforts we expect that to change in the near future.

Durability And Build Quality

The durability of your small diameter borescope is vital, especially if it will be used in rugged industrial environments. Look for a borescope with a robust construction that can withstand exposure to harsh chemicals, extreme temperatures, or potential impacts. Stainless steel or tungsten braided cables are often used for their durability.

Battery Life And Portability

Consider the battery life and portability of the borescope. Longer battery life ensures uninterrupted inspections, while portability allows easy transportation to different job sites. Some models offer rechargeable batteries, while others rely on disposable ones. Make sure the battery type aligns with your operational needs.

Connectivity And Data Storage

Modern small-diameter borescopes often come equipped with connectivity options. Some models offer Wi-Fi or USB connections, allowing you to transfer images and videos to a computer or mobile device for analysis and documentation. Others may include onboard storage for capturing and saving inspection data directly on the device.

Budget And Cost Of Ownership

Last but not least, consider your budget and the overall cost of ownership. While it’s tempting to opt for the most feature-rich borescope, balancing your needs and budget is essential—additionally, factor in ongoing costs, such as maintenance, calibration, and potential repairs.

Conclusion

Choosing the right small-diameter borescope for your inspection needs is a critical decision that can significantly impact the efficiency and accuracy of your operations. By defining your purpose, considering the diameter and length, prioritizing image quality, evaluating articulation and maneuverability, assessing durability, reviewing battery life and connectivity options, and managing your budget effectively, you can make an informed choice that aligns with your specific requirements. Remember that investing in the right borescope can lead to improved inspection results and long-term cost savings.