Engine borescopes have become essential in aviation, automotive, and industrial maintenance for providing clear, non-invasive visual inspections. It allows technicians to inspect the inside of an engine without tearing it down, giving a clear view of internal components fast, safely, and without the risk or downtime of disassembly.

But what is an engine borescope, and how is it used? This guide will walk you through everything you need to know, including the types available, and how they’re used across various industries and applications.

What Is an Engine Borescope?

An engine borescope is a precision inspection tool designed to inspect hard-to-reach areas of engines, turbines, and other machinery. It uses a rigid or flexible probe with a high-resolution camera and built-in lighting to deliver live images or video to a display.

This allows operators to view the engine’s inner workings without opening it. It’s become a standard tool for detecting wear, carbon buildup, cracks, FOD, and other issues that aren’t visible from the outside.

Types of Engine Borescopes

Different inspections call for different borescope designs. The three most common options are:

-

Rigid Borescopes

Rigid borescopes feature a solid, straight tube with a fixed viewing angle and provide high-quality, undistorted images. They are often used for short, direct inspections where you have a straight line of access, such as checking certain turbine stages or simple housings.

-

Flexible Borescopes (Fiberscopes or Videoscopes)

Flexible borescopes use fiber-optic or video technology, allowing the camera to navigate bends and curves within the engine. These are ideal for inspecting areas like cylinder heads, combustion chambers, and exhaust paths.

-

Videoscopes

Videoscopes integrate a miniature camera at the tip of a flexible probe, providing live video on an external display. Many modern videoscopes also include measurement capabilities, recording, and annotation features, making them highly versatile.

How Is an Engine Borescope Used?

Regardless of where they’re used, engine borescopes all serve one function: giving technicians a clear internal view without disassembly.

Here’s how they are commonly applied:

Automotive Maintenance and Repair

Technicians use engine borescopes to inspect internal components such as pistons, valves, cylinder walls, and turbochargers. By inserting a borescope through the spark plug hole or intake/exhaust ports, mechanics can detect carbon buildup, wear, corrosion, or cracks without removing the head or breaking down major components.

This reduces downtime, labor costs, and the risk of introducing new issues during disassembly.

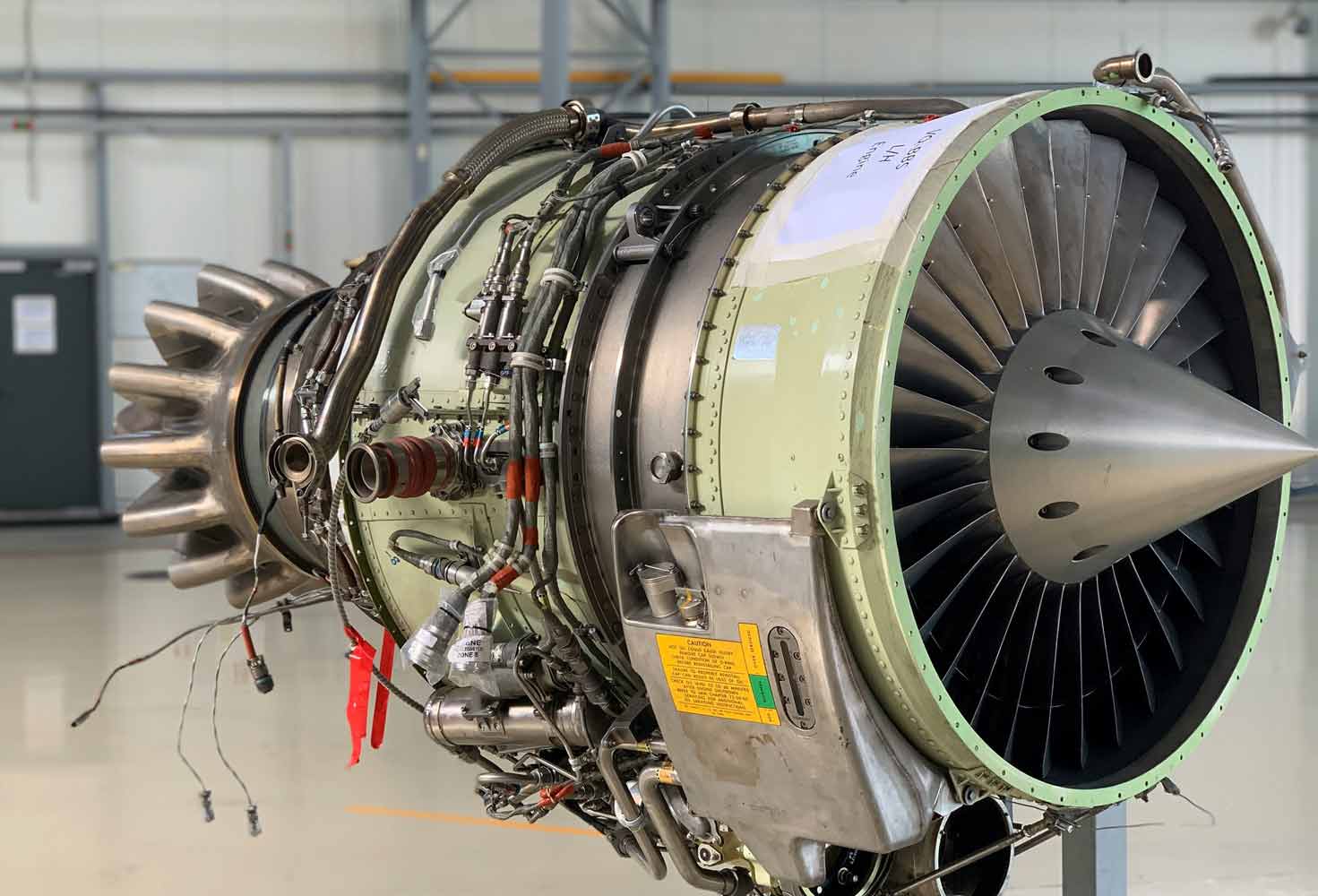

Aviation Engine Inspections

Aircraft engines require regular and rigorous inspections to ensure safety and compliance with Federal Aviation Administration (FAA) standards. Engine borescopes allow technicians to examine turbines, compressors, and combustion chambers for cracks, foreign object damage (FOD), or corrosion.

Using borescopes in aviation improves efficiency and ensures that engines meet stringent safety requirements without extensive disassembly.

Industrial Equipment Maintenance

Large engines, generators, compressors, and industrial turbines are routinely inspected with borescopes to monitor internal wear and alignment. These checks help maintenance technicians and reliability engineers catch early signs of failure before they disrupt operations and lead to costly breakdowns.

Preventive Maintenance

Borescopes are not just for troubleshooting problems; they are also essential for preventive maintenance. By performing regular inspections, businesses can catch early signs of damage, extend the life of engines, and improve overall reliability.

Benefits of Using Engine Borescopes

Understanding what an engine borescope is also means recognizing the advantages it brings to maintenance and inspection operations:

- Non-Invasive Inspections: Reduce the need for engine disassembly, saving time and labor costs.

- Early Problem Detection: Identify wear, cracks, corrosion, or foreign object damage before they escalate.

- Cost Efficiency: Preventive inspections reduce expensive repairs and unplanned downtime.

- Versatility: Suitable for automotive, aviation, and industrial engines, as well as turbines and compressors.

- Documentation: Modern borescopes can record images and video for reporting, compliance, and analysis.

Tips for Using Engine Borescopes Effectively

To get the most out of an engine borescope, consider the following best practices:

- Choose the Right Type: Flexible for curved paths; rigid for straight-shot clarity

- Proper Lighting: Strong illumination improves visibility of hairline defects

- Training: Skilled handling prevents false diagnoses and protects components

- Documentation: Record inspections for maintenance records, troubleshooting, or regulatory compliance

Why Engine Borescopes Are Essential for Modern Maintenance

Modern engines are complex, tightly packaged, and expensive to tear down. An engine borescope provides the internal visibility you need to make confident maintenance decisions quickly, safely, and without unnecessary disassembly.

Whether you’re working on aircraft engines, automotive systems, or industrial turbines, borescopes help you detect issues earlier and keep equipment running reliably.

Ready to Improve Your Inspections with a USA Borescope Tool?

At USA Borescopes, we offer a wide selection of high-quality engine borescopes, videoscopes, and inspection cameras designed for precision and durability.

Explore our full range or contact our team for expert guidance on choosing the best borescope for your needs.