Keeping aircraft engines airworthy requires more than routine checks—borescope inspections allow technicians to see inside turbines, compressors, and combustion chambers without disassembly. By following a structured checklist, maintenance teams can detect hidden cracks, wear, or foreign object damage early, preventing costly failures and ensuring FAA compliance.

Month: September 2025

What Is the Purpose of a Drain Clean-Out?

A drain clean-out may look like a simple capped pipe, but it’s one of the most important parts of your plumbing system. It provides direct access to your sewer line, allowing plumbers to quickly clear clogs, perform camera inspections, and prevent costly backups. When paired with a borescope, it becomes a powerful tool for diagnosing hidden pipe damage and keeping your home protected from sewage overflow.

USA Borescopes Lands at St. Louis Aviation Maintenance Symposium 2025

USA Borescopes is excited to announce its participation in the St. Louis Aviation Maintenance Symposium 2025, held at the Crowne Plaza St. Louis Airport in Bridgeton, Missouri. This one-day event brings together aviation maintenance professionals for technical...

USA Borescopes Heads to Houston for TPS 2025 — Over 50 Years of Innovation and Still Pumping!

USA Borescopes is thrilled to announce its return to the Turbomachinery & Pump Symposia (TPS 2025), happening at the George R. Brown Convention Center in Houston, Texas. Now in its 54th year, TPS is the go-to gathering for engineers, technicians, and...

Pressurized Pipe Inspection: Techniques and Best Practices

Inspecting pressurized pipes requires precision, safety, and the right technology. Whether you’re working in industrial, plumbing, or utility environments, using tools like borescopes, ultrasonic sensors, and pressure monitoring systems allows you to detect leaks, corrosion, or cracks without shutting down operations. With proper preparation and technique, pressurized pipe inspections can prevent costly failures, extend equipment life, and ensure compliance with safety standards.

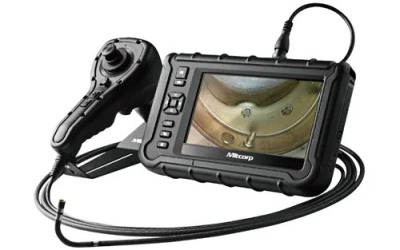

How to Use an Inspection Camera: Step-by-Step

An inspection camera makes it easy to see inside pipes, engines, or tight spaces without tearing things apart. Whether you’re troubleshooting a clog, checking for corrosion, or inspecting machinery, using one is simpler than you think. With the right equipment and a methodical approach—insert, observe, document, and clean—you can pinpoint problems quickly and avoid costly guesswork. USA Borescopes provides tools designed for clear visuals and reliable performance in every inspection.

Borescope usage for Safe Nuclear Power Inspections

In the complex environment of nuclear power plants, safety and precision are non-negotiable. Regular and thorough inspections play a major role in ensuring safety and efficiency—but these are often high-risk procedures that involve examining high-radiation,...

Enhancing Safety during Nuclear Inspections with Borescopes

Summary: The use of USA Borescopes' range of videoscope products during nuclear inspections keeps power plants' safety a top priority, adding value and efficiency for long-lasting plant integrity. Remote visual inspection specialist, USA Borescopes, play a key role in...

Minimizing Radiation Exposure with Borescopes

Successful inspection technology firm USA Borescopes has unveiled a new generation of advanced nuclear borescopes, designed to drastically minimize radiation exposure for nuclear and industrial inspectors through remote visual inspections that enhance worker safety,...

USA Borescopes State-of-the-Art Technology For Nuclear Monitoring

USA Borescopes inspection solutions make nuclear monitoring both safer for personnel and easier for organizations! USA Borescopes provide an array of remote visual inspection scopes that offer a non-destructive testing approach. These scopes are ideal for use across a...